DIY Steam Blower from a Clothes Iron

This is a cool project from an old, broken iron steam station. It turns out a useful home made powerful steam blower!

This steam blower can be useful for cleaning, melting glue and wax, doing (impure) extraction of oil from seeds, or

essences from spices and other vegetal sources, degreasing/dewaxing, removing residues of solvents, enhancing the

action of detergents and chemicals, etc.

There are so many applications that make this tool something that sooner or later will come handy.

Let's say you need to clean a PCB? A steam cleaner is very useful for the job maybe before ultrasound treatment.

⚠ Caution. This project requires some skills and proper materials otherwise the resulting product could be quite dangerous because hot water, steam and electricity are all present in the same confined space, so I discourage naives to make this thing, because you really must know what you do, how to properly seal electric wires hot-water proof!

The switch is peculiarly tricky so I've made one myself. In this article you can read more about how to make a sealed switch, and you'll find a link to a video where I show how I made a sealed swicth able to withstand this harsh environment and withstanding almost 1000V.

For the handle I've used hardwood saturated with bi-component polyester, and Silicone chaulk for hot water as sealant, both able to withstand up to 180C.

DO NOT use softwood, and wood MUST be saturated with resin, insoluble at high temperature. Phenolic resins are ideal (since they are thermosetting), even though somewhat toxic (they tend to release phenols when heated). A healthier alternative (when set) is a bi-component polyester which however usually do not hold more than 120C (industrial grade may reach up to 180C, thogh).

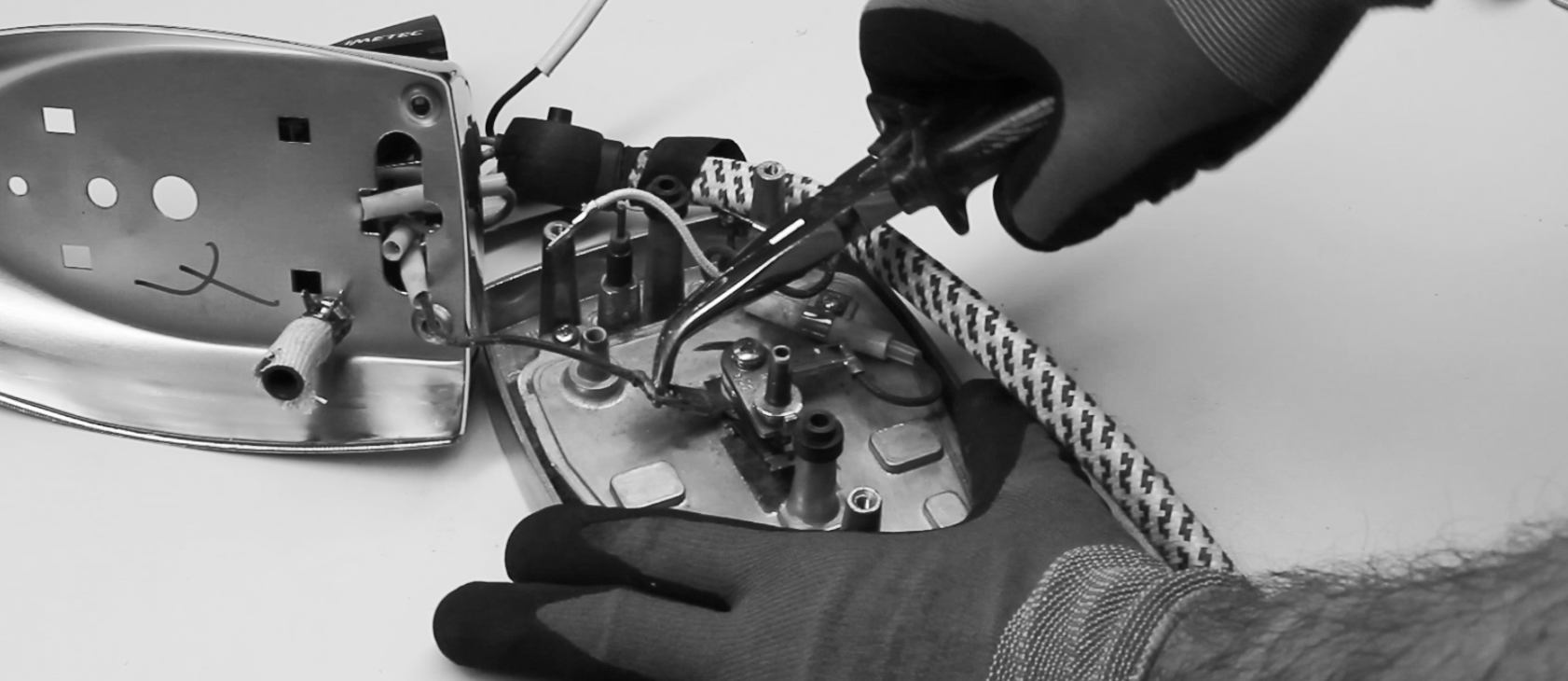

Since we re-use the steam station mostly as-is, the large part of the job is about making the steam gun and nozzle.

As mentioned before it is made of hard-wood, in my case I used beechwood. I picked a piece already available as a rod,

that I machined with a simple drill press and some hand tools.

The part was coated with polyester resin and a layer of paint for aesthetic reasons.

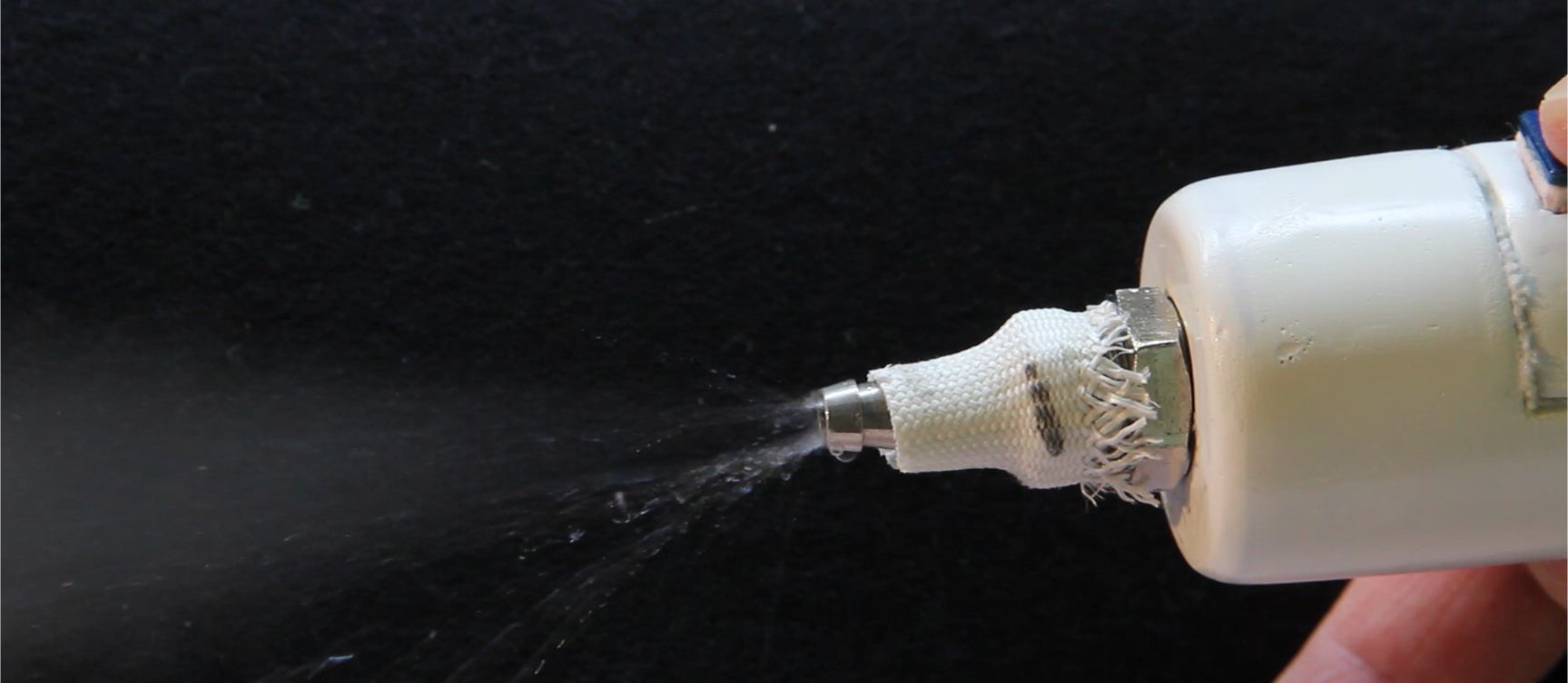

The nozzle was quite tricky. At first I used a common hydraulic hose fitting made of nickel coated brass, but as you can

see in the picture below it was a source of problems as the steam is cooled down by the relatively large mass of brass.

After some use the nozzle become hot enough to let this problem disappear, but in the mean time the steam chamber lose

pressure... Clearly it wasn't a solution.

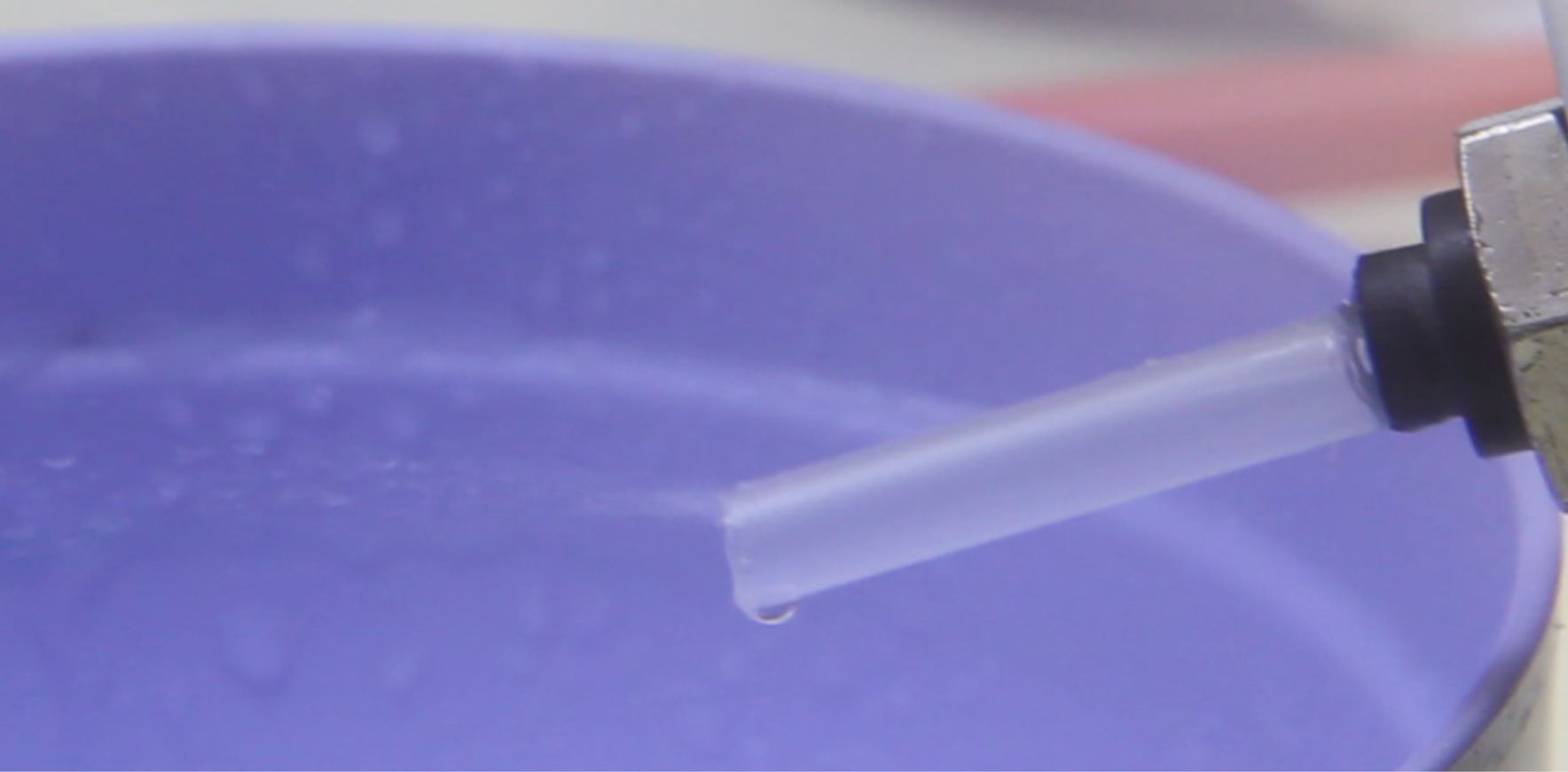

So the solution was to change the nozzle using a small plastic tube. The steam is less cooled down and a remarkable smaller amount of water condensation happens.

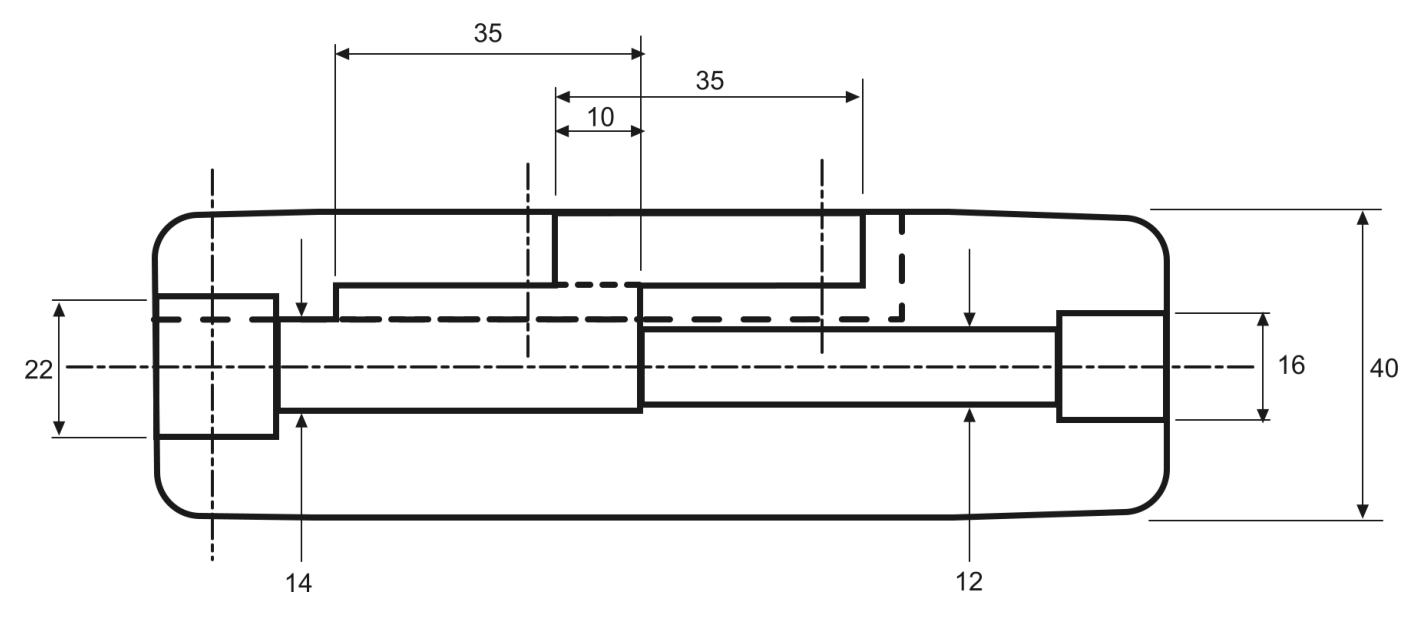

Here a drawing of the steam gun:

Watch the video to learn more.

Don't miss next post

Subscribe to stay up to date when new articles, videos or other contents are available.

RELATED ARTICLES

RECENT ARTICLES

Subscribe

Subscribe![Validate my Atom 1.0 feed [Valid Atom 1.0]](../valid-atom.png)